How swift? Precisely at 30 seconds per unit, according to Nikkei Asian Review.

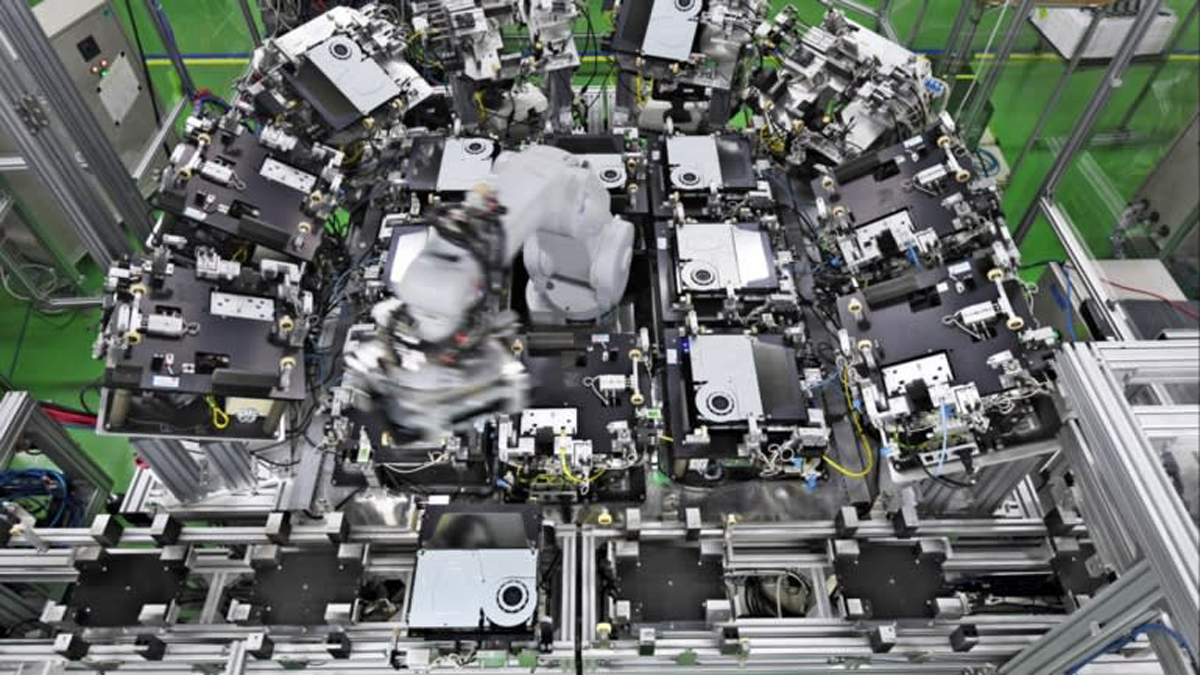

The Kisarazu factory is operated by Sony Global Manufacturing & Operations (SGMO) and features a 103-foot assembly line that was completed in 2018, designed specifically to produce PS4 units. It consists of 32 robots supplied by Mitsubishi Electric, which allows a near automated assembly for each unit with minimal human involvement in the process. According to Nikkei’s report, only four Sony staff members are present during the device’s production. Specifically, two individuals feed the PS4’s motherboard to the assembly line, and another two handle the packaging of the finished product.

“There’s probably no other site that can manipulate robots in this manner,” one of the site’s engineers told Nikkei. “The blend of robotic and human labor is painstakingly optimized with a priority on return on investment.” It’s quite likely that Sony will apply a similar approach for the upcoming Playstation 5 console in the near future, if not already. Provided that it becomes a success after launch, the company will definitely need to produce a staggering large number of PS5 consoles in the shortest amount of time to keep up with demand. (Source / Images: Asia Nikkei Review)